Our Hot Selling Equipment

Top Waste Tire Recycling Machine Manufacturer

In China With Customized Solution

We provide complete turn-key tire recycling solution from R&D, production until successfully installation at customer’s worksite. - designed to turn waste tyres into valuable products with maximum efficiency. From high-performance shredders to versatile and durable solutions, HVST offers a wide range of customization equipment to meet your tyre recycling needs and ensure profitability in your operations.

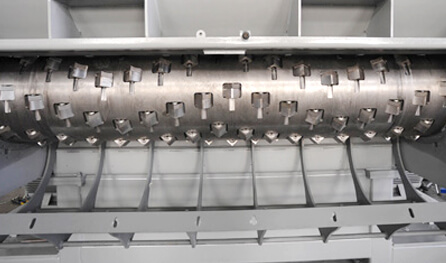

The single shaft shredder utilizes cutters mounted on the rotor to shred materials through rotation, offering material adaptability, high throughput, small finished size and consistent performance. With screens designed specifically for single-shaft shredders, it is easy to meet the required final size of material in a single pass with just one single machine.

HVST's single-shaft shredders are manufactured with highly wear-resistant, high-strength and tough cutters, manufactured in different materials according to the material characteristics and installed in different formats, thus guaranteeing a wide range of material adaptability and flexibility. HVST's single-shaft shredders are not only used by waste management and recycling companies, but in hotels, recycling stations and personal projects.

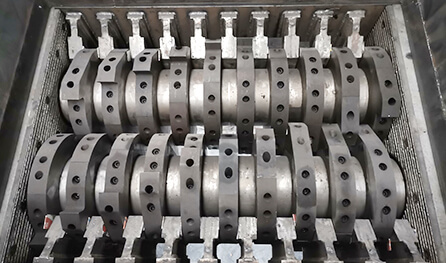

Double shaft shredders are advanced and robust machines that play a vital role in waste management and recycling industries. A double shaft shredder, also known as a dual shaft shredder, consists of two parallel shafts equipped with rotating blades or discs.

These shafts rotate in opposite directions, creating a shearing and tearing action that effectively breaks down various materials.

The double shaft design enhances the shredding efficiency and capacity of the shredder machine, making it suitable for heavy-duty applications.

four-shaft shredder has four sets of shear rolls with different tool configurations to match each other. Once inside the shredding chamber, the material is shredded into small pieces by the tearing and shearing action of the blades on the four sets of rolls. The size of the output material is controlled by the screen. After the material is cut once, the material with a smaller particle size than the hole of the screen is discharged from the lower part of the box under the action of gravity and squeezing pressure, while the material with a larger size than the hole of the screen is guided by the main cutters and the secondary cutters to return to the inner surface of the screen for the second cutting, and so on until the material can be discharged from the hole of the screen.

HVST offers a high performance heavy duty four-shaft shredder for large applications. It uses a high horsepower motor in combination with a large high speed ratio reducer, making it easy to cope with the disposal of bulky waste, car shells, non-ferrous metals, various industrial and hazardous waste.

HVST has the right machines for a volume reduction and controlled size shredding processes.

Industrial Shredders are used in a wide range of applications in recycling and waste disposal industry in reducing size or volume in large batches by shearing, tearing or crushing. It is divided into single-shaft shredders, double-shaft shredders and four-shaft shredders. Double-shaft shredder meets most material disposal requirements thanks to its high shredding ratios, consistent work efficiency and low failure rates.

Single-Shaft Shredder

Double-Shaft Shredder

Four-Shaft Shredder

As one of the most important industrial shredder machines, four shaft shredders find applications in various industries and waste management processes. They are commonly used for shredding bulky and tough waste materials, such as plastic bottles, containers, pallets, wood scraps, cardboard, metal drums, tires, and more. Four shaft shredders are widely utilized in recycling facilities, waste-to-energy plants, municipal solid waste management centers, and industries that generate significant volumes of waste.

1. Waste Tires

2. WEEE: scrap electric and electronic material waste, electric cables

3. Scrap Cars: parts coming from the vehicle demolition (bumpers, tanks, dashboards, sheet metal)

4. Plastic: tubes, lumps, films

5. Wood: pallet, branches

6. Paper and Cardboard

1. Scrap Metal: aluminum and metal profiles, oil barrel, miscellaneous collection cans

2. Bulk Waste: sofas, mattress

3. Waste Food

4. Hazard and Medical Waste

5. Composite Materials

6. Industrial Waste in General