Our Hot Selling Equipment

Double-Shaft Waste Shredder

Double shaft shredder is a powerful equipment that can crush large, difficult-to-shred or hard-to-transport materials into small pieces by shearing, squeezing and tearing, to meet the shredding requirements. It has the characteristics of low speed, high torque, strong power, good stability, adjustable discharging particle size, wear resistance, strong load-bearing capacity, easy operation, cost reduction and efficiency improvement.

HVST Double shaft shredder is mainly composed of blade spindle, fixed knife, carrying box, box bracket, feeding system, hydraulic pushing system, power system, and electrical control system. Adopts an advanced PLC detection control system, which is equipped with start, stop, reverse and overload automatic reverse control functions. It has the characteristics of low energy consumption, large processing capacity, high torque, low noise, and low maintenance cost, and is suitable for crushing and processing over a hundred types of waste.

1. Low speed, high torque rotor, crushing efficiency improve significantly, suitable for both soft and hard materials.

2. Large chassis, high safety level, ultra-large capacity, sturdy and reliable, strong impact resistance.

3. High performance well-known motors and reducers are available for different customers options, driving force is stable.

4. Overload reversing function, stop, forward rotation are set on the cabinet controller, minimizing blades damages.

5. Individual electrical control panel with PLC control system ensure the machine work properly and safety.

6. Alloy cutting blade, imported material, high strength and good wear resistance, easy replacement and maintenance.

four shaft shredder

Removable blades in various sizes

Fully automatic PLC control

industrial shredding machine

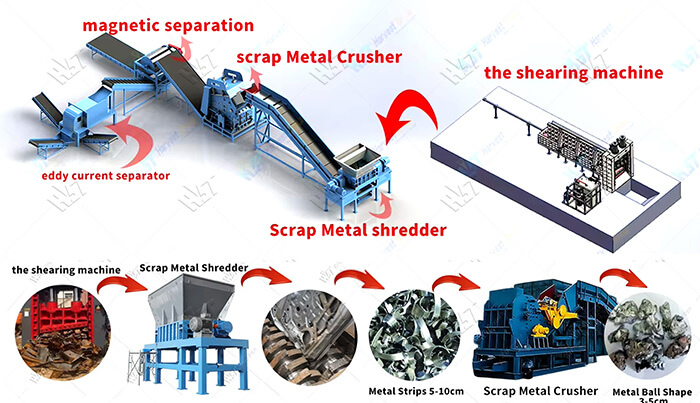

We have different metal crusher systems to meet different market needs. Type1:

1. the shearing machine

2. Doubel shaft shredder

3. Metal crusher

4.Central dust removal system

5. magnetic separator

6. Eddy current sorter

7. Output conveyour.

Type2: Scrap steel shearing and crushing process

Type3: Scrap steel shearing and shredding process Please leave a message for your requirements, the machine can be customized for you.

LK-MS2400 Metal Shredder is specially designed for shredding waste metal like car, steel, aluminum, steel wire, cooper into clean-cut primary scraps down to size.

1. Waste Tires

2. WEEE: scrap electric and electronic material waste, electric cables

3. Scrap Cars: parts coming from the vehicle demolition (bumpers, tanks, dashboards, sheet metal)

4. Plastic: tubes, lumps, films

5. Wood: pallet, branches

6. Paper and Cardboard

1. Scrap Metal: aluminum and metal profiles, oil barrel, miscellaneous collection cans

2. Bulk Waste: sofas, mattress

3. Waste Food

4. Hazard and Medical Waste

5. Composite Materials

6. Industrial Waste in General

HVST Machinery has 19 years of technology accumulation and specializes in the production of solid waste recycling equipment, such as biomass waste, waste tires, scrap metals, large waste, industrial waste, agricultural and forestry waste, etc., and provides targeted recycling solutions. Our products have obtained multiple patents and CE, ISO certifications. At present, our solid waste recycling projects cover Poland, Czech Republic, Romania, Russia, South Africa, Algeria, Brazil, Saudi Arabia and many other countries.

|

Metal shredder |

MS2400 |

MS1800 |

MS1600 |

MS1300 |

MS1200 |

|

Motor |

Siemens |

Siemens |

Siemens |

Siemens |

Siemens |

|

Power |

110kw*2 |

75kw*2 |

55kw*2 |

45kw*2 |

37kw*2 |

|

Voltage |

As per request |

As per request |

As per request |

As per request |

As per request |

|

Cutting chamber L*W |

2400*1800 |

1804*1410 |

1504*1360 |

1304*920 |

1204*920 |

|

Blade Diameter |

1000mm |

750mm |

530mm |

480mm |

480mm |

|

Equipment Dimensions L*W*H |

7300*2438*1046 |

5870*2450*3890 |

5260*2420*3890 |

5120*2010*3100 |

5010*1710*3100 |

|

Equipment weight |

60000kg |

23000kg |

20000kg |

16000kg |

14000kg |

|

Hopper Opening L*W*H |

3711*2438*1046 |

2790*2450*1100 |

2760*2410*1100 |

2050*1650*1000 |

1850*1650*900 |

|

Final Product |

110-300mm |

75-150mm |

60-100mm |

60-100mm |

50-100mm |