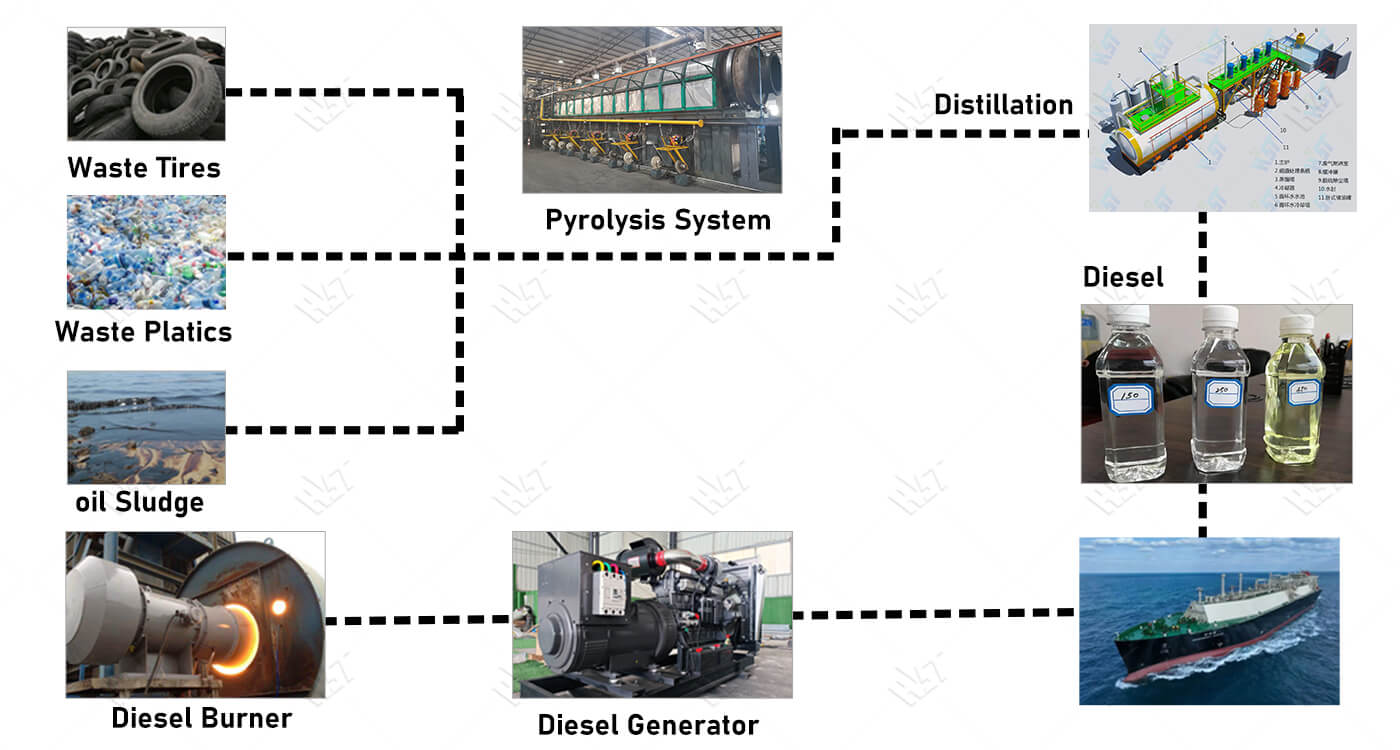

Distillation equipment is a device used to separate liquids into their constituent parts.

Distillation equipment heats a mixture to bring one or more components to boiling point and convert them into a gaseous state,

and then condenses these gaseous components back into a liquid state to obtain a pure single component or mixture.

Sediment

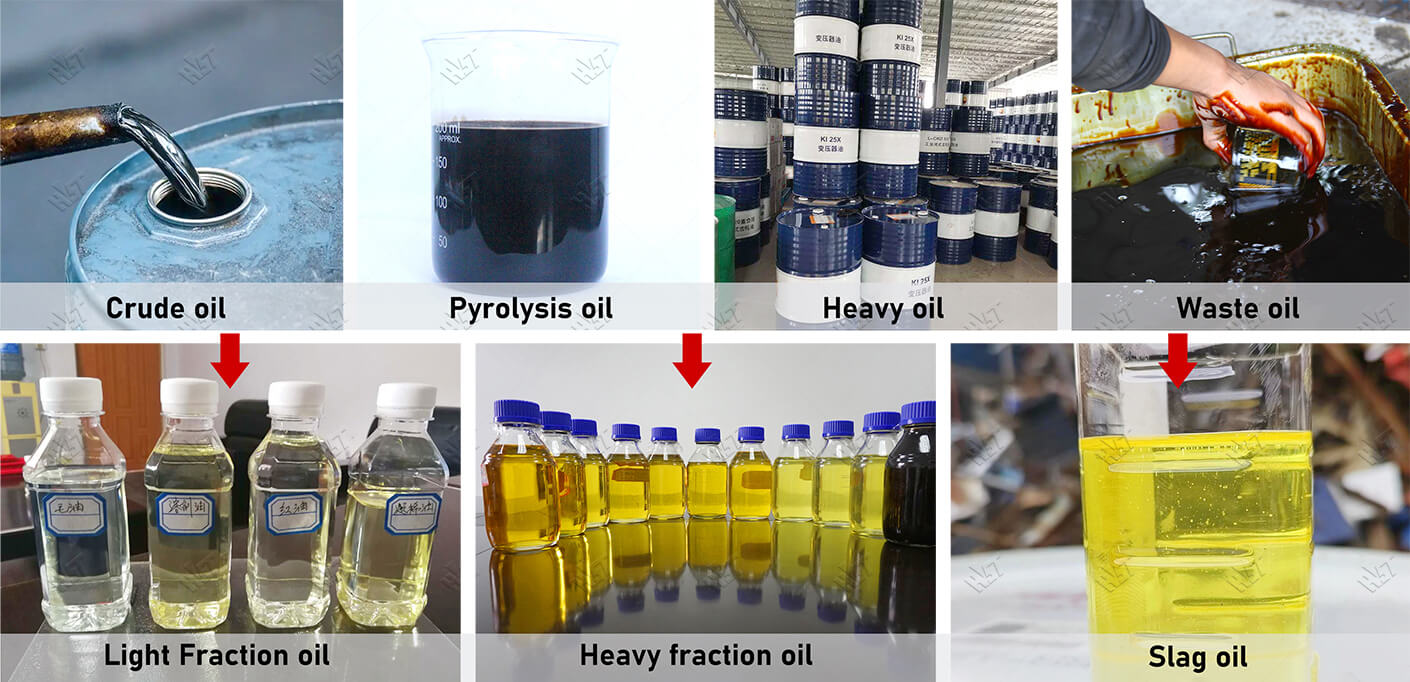

Waste oil or pyrolysis oil will be collected and stored in big tanks, make the big size impurities sink to the bottom, when loading , leave the bottom impurities.

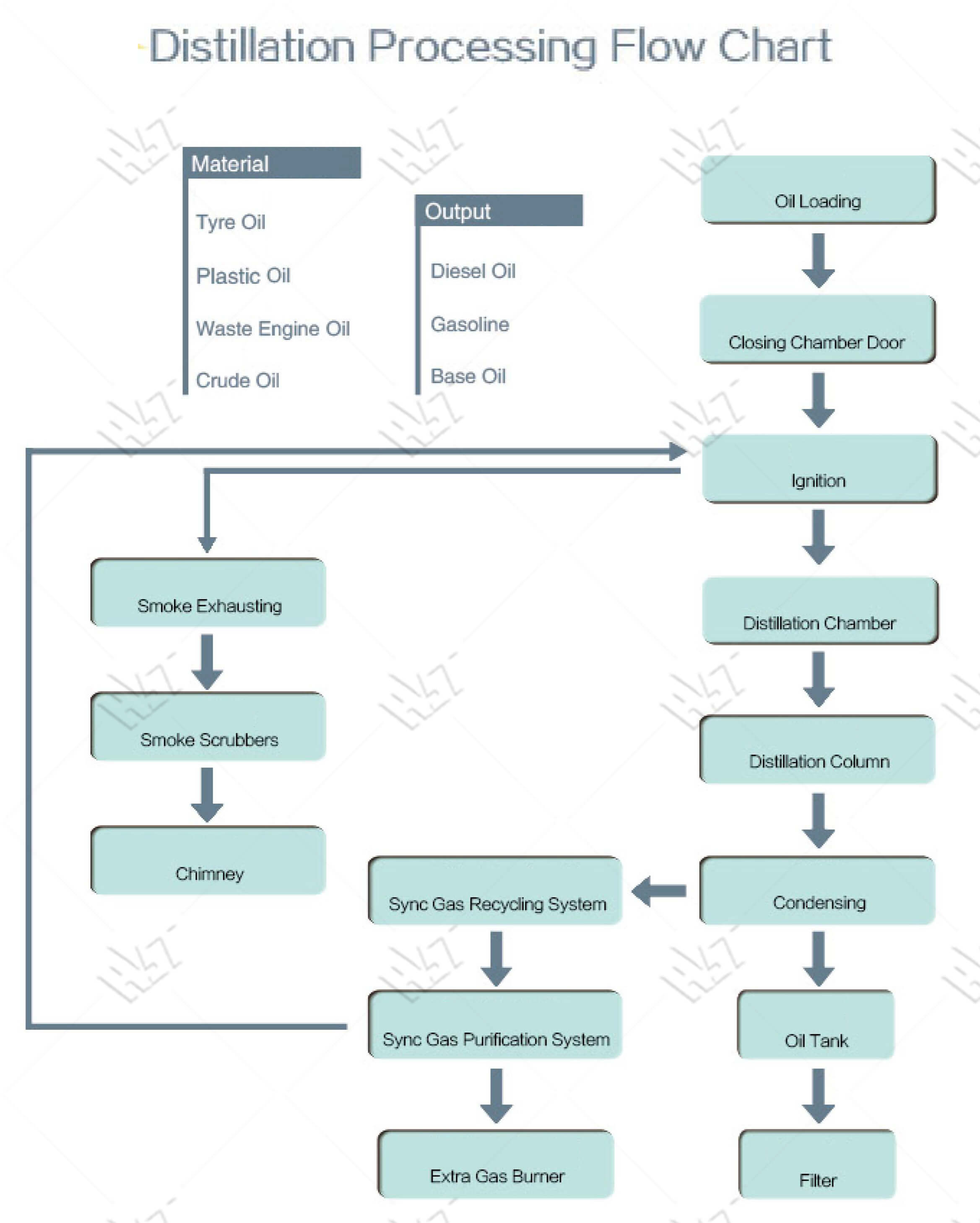

Distillation

Pumping the oil into the distillation reactor, and start heating, highest temperature in the system should be around 350 ℃, under vacuum production environment, to keep safety of operation, liquid oil heated to become oil gas, then condensed into liquid oil again and stored in the oil tank, this process help to separate light oil from the impurities.

Acid washing

Acid washing is to mix a fix quantity of H2SO4 with the oil, to make the impurities precipitate out, to improve the color and smell of the oil, the concentration of the H2SO4 should be more than 98%, Concentrated sulfuric acid has strong oxidizing property, could generate sulfonation, oxidation, esterification with the nitrogen, oxygen, sulphur containing compounds, thus, this process also has very obvious function to remove the sulphur in the oil.

Alkaline Washing

The main purpose of Alkaline washing to neutralize the acid in the oil, the make the PH of the oil to be 7.

Activated clay treatment

Activated clay has strong chemical and physical adsorption function to the impurities, which will help to improve the color of the oil and make it more stable.

Filter press

Filter process is to separate the impurities in the oil by pressing the oil through filter cloth, the oil will be cleaner after this process.

Efficient separation: It can accurately separate substances with large boiling point differences and obtain high-purity products.

Strong adaptability: Suitable for separating various mixtures, parameters can be adjusted according to needs.

Energy conservation and environmental protection: The design emphasizes energy efficiency, reduces energy consumption, and conforms to the trend of green chemistry.

Easy to operate: equipped with a friendly interface and intelligent system, reducing operational difficulty and improving efficiency.

Safe and reliable: equipped with safety functions such as overheating protection, simple structure, and easy maintenance.

Data recording: Automatically recording key parameters helps with subsequent analysis and optimization of experimental conditions.

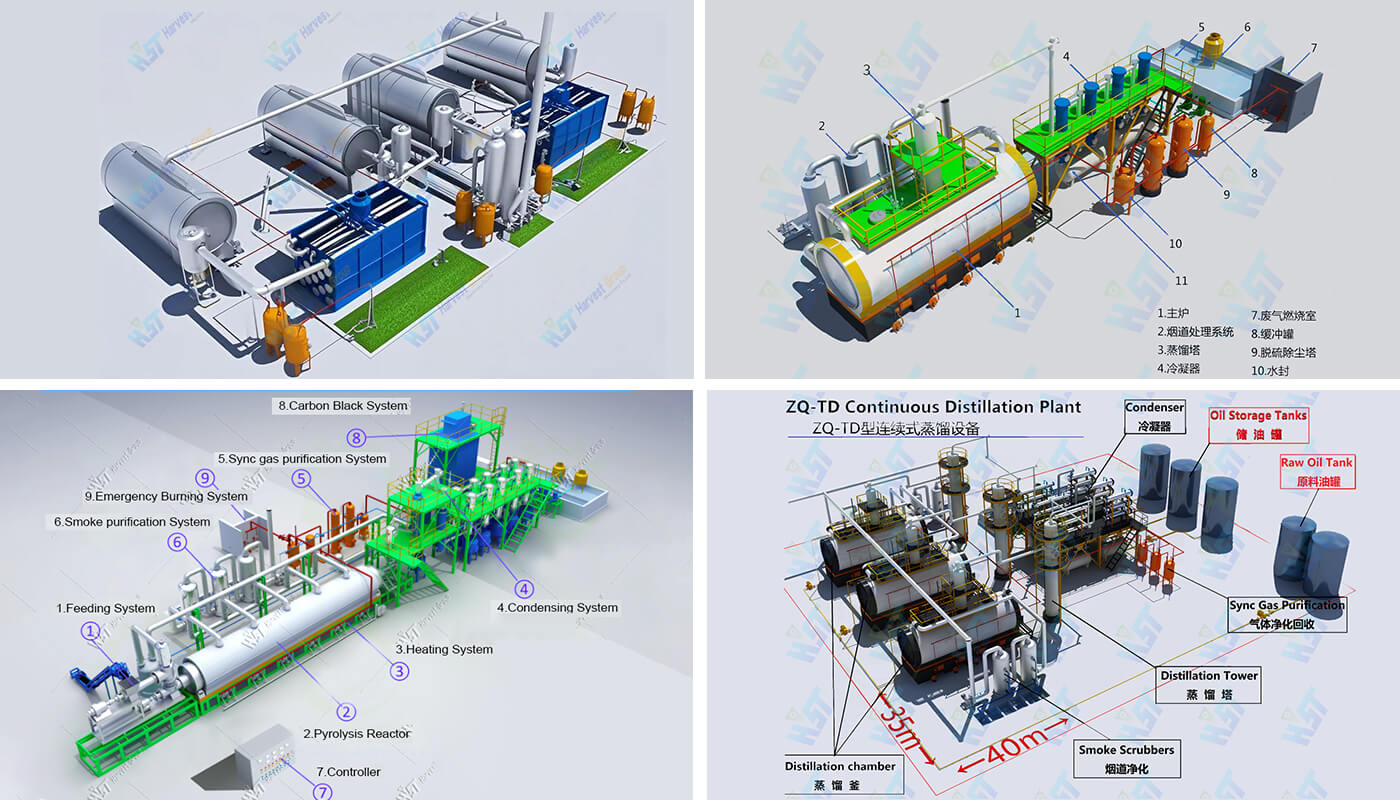

We have distillation equipment and continuous distillation equipment that can meet the production capacity of 10t-300t.

Type 1 Distillation equipment features: semi continuous upgrade; Unique horizontal design; Efficient condenser; Synchronous gas recovery combustion;

Type 2 Continuous distillation equipment; Large processing capacity; Fully continuous production; Fast heating; Non stick to the wall; Easy to clean; Good quality of produced oil products;

|

NO |

ITEM |

PROJECT |

|

|

1 |

Equipment Model |

XY-1-D |

XY-8-D |

|

2 |

Suitable Raw Materials |

Waste Engine oil,Fuel Oil,Crude Oil |

Waste Engine oil,Fuel Oil,Crude Oil |

|

3 |

Structure |

Horizontal Type |

Horizontal Type |

|

4 |

Capacity (24hours) |

3~4Mt 5-6Mt 8-10Mt |

3~4Mt 5~6Mt 8~10Mt |

|

5 |

Work Pressure |

Normal Pressure |

Normal Pressure |

|

6 |

Oil Yield |

85%-95% |

85%-95% |

|

7 |

Power |

15-25kw/H |

15-25kw/H |

|

8 |

Heating Method |

Indirect Heating |

Indirect Heating |

|

9 |

Type of Installation |

Without Foundation |

With Foundation |

|

10 |

Noise dB (A) |

≤85 |

≤85 |

|

11 |

Chamber Size |

∅2200 x 6000mm |

∅2200 x 6000mm |

|

∅2500 x 8800mm |

∅2500 x 8800mm |

||

|

∅2500 x 11000mm |

∅2500 x 11000mm |

||

|

12 |

Operating Mode |

semi-continuous Operation |

Semi-continuous Operation |

|

13 |

Cooling Method |

Cycling Water |

Cycling Water |

|

14 |

condensers |

3 Pieces of Horizontal Condensers |

4Pieces of Vertical Condensers |

|

15 |

Installation Space Required |

30m x12m |

35m x15m |

|

16 |

End Product |

Non-standard Diesel Oil |

Non-standard Diesel Oil |

|

17 |

Manpower |

1~2/shift |

1~2/shift |